Cestari S-TECH 990 Track System

Versatility, flotation, and stability for your hoppers.

- Reduced compaction

- Increased productivity

- Fuel savings

- Improved trafficability

- Improved pulling power

- Quick and easy installation

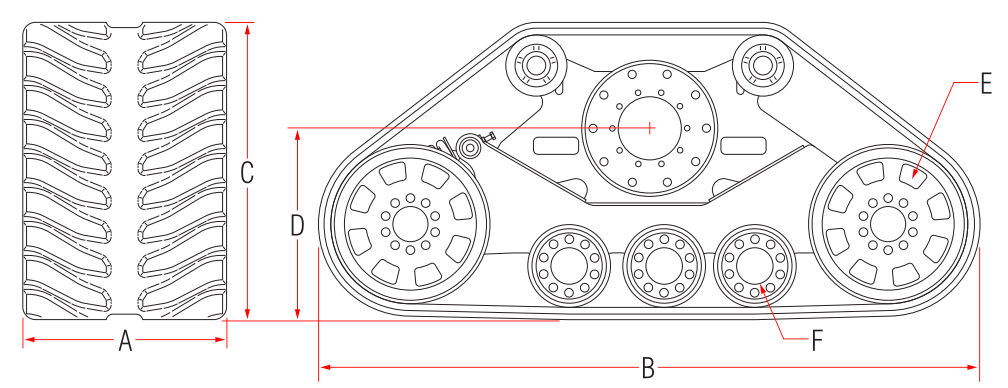

A. Track width: 914 mm

B. Overall length: 2,969 mm

C. Overall height: 1,331 mm

D. Slewing axle height: 856 mm

E. Rear idler wheel diameter: 711 mm

F. Support wheel diameter: 368 mm

Weight: Approx. 4,520 kg

Transport load capacity: Up to 22,700 kg

Maximum transport speed: 26.5 km/h

Ground load capacity: 41,000 kg

Total contact area: 3.93 m² (2 tracks)

- DYNAMIC TENSIONER: Removes debris with the rotation of the track without slowing it down.

- ANNUAL MAINTENANCE: Every 200-300 hours, without weekly greasing.

- NARROW PROFILE: Narrower than dual-track wheels, making unloading easier.

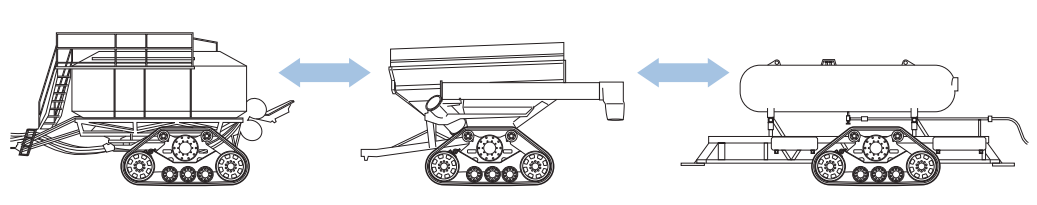

- VERSATILITY: Easy installation on various agricultural platforms.

Hopper Track System.

Versatility, Floatation, and Stability

The S-TECH 990 offers less rolling resistance thanks to better weight distribution over a larger ground contact area.

With a track width of 914 mm, the track ensures optimal flotation in soft soils.

Perfect for farmers looking for a versatile track system for their hoppers and equipment.

DYNAMIC TENSIONER

The spring tensioning system continuously removes debris. The spring inside the wheel neutralizes the compression to expel debris as the track system rotates, without slowing it down.

NARROW PROFILE

The S-TECH 990 track system is narrower than the dual wheels typically used on a dump truck. Measuring only 914.4 mm (36 inches) wide, compared to dual-wheel systems that can reach 1,397 mm (55 inches), the S-TECH 990 allows it to get considerably closer to trucks for easier unloading. Road transport is also safer thanks to its narrow width.

ANNUAL MAINTENANCE

The new S-TECH track system requires annual maintenance or every 200 to 300 hours of use.

You don’t have to worry about greasing the axles every week, which means more time to focus on the jobs that really matter.

VERSATILITY

The bolt-on design allows for easy installation on a wide range of hoppers and equipment, from a pneumatic seeder in the spring to a trailer in the fall.